Kobelco machines are reliable and powerful pieces of industrial equipment used in a wide variety of applications. They require regular maintenance and servicing to ensure their optimal performance. This article provides an overview of the servicing and troubleshooting of Kobelco machines, so that users can get the most out of their machines.

Introduction to Kobelco Machines

Kobelco machines are renowned for their quality and durability. They have been used in a wide range of industries, including mining, construction, and manufacturing. Kobelco machines are designed to be robust and reliable, and they are built to last. They are also easy to use and maintain, making them ideal for use in a variety of environments.

Kobelco machines are available in a variety of sizes and configurations, so they can be adapted to meet specific needs. They are also highly customizable, so users can add features and accessories to suit their specific needs. Kobelco machines are also designed to be energy efficient, so they can help to reduce operating costs.

Servicing Kobelco Machines

Kobelco machines require regular servicing and maintenance to ensure optimal performance. The manufacturer recommends that machines be serviced every 500 hours of operation, or at least once a year. During the service, the machine should be inspected for any signs of wear and tear, and any necessary repairs should be made.

The service should also include an oil change, as well as a check of the machine’s filters and other components. It is also important to check the machine’s lubrication system, and to ensure that all of the parts are properly lubricated. The service should also include a check of the machine’s electrical system, and any necessary repairs should be made.

Troubleshooting Kobelco Machines

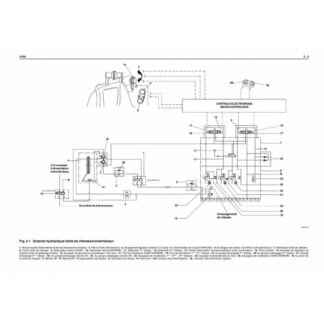

Kobelco machines are generally reliable, but they may occasionally experience problems. If a machine is not functioning properly, it is important to troubleshoot the issue in order to identify the cause. Common problems with Kobelco machines include electrical issues, mechanical problems, and hydraulic issues.

If the machine is experiencing an electrical issue, it is important to check the wiring and connections. If the machine is experiencing a mechanical issue, it is important to check the parts for signs of wear and tear. If the machine is experiencing a hydraulic issue, it is important to check the pressure and flow of the hydraulic system.

It is also important to check the machine’s filters and other components for signs of debris or contamination. If the machine is not functioning correctly, it is important to contact a qualified technician to diagnose and repair the issue.

Kobelco machines are reliable and powerful pieces of equipment that require regular servicing and maintenance. By following the service guide and troubleshooting any issues, users can ensure their machines are functioning optimally. By taking good care of their machines, users can enjoy the benefits of Kobelco machines for many years to come.